Salvador Dali

Salvador Dali was a Spanish painter and graphic artist who focused on the use of emotional language to convey meaning. His paintings are characterized by their seemingly ordinary subject matter, Continue Reading

Salvador Dali was a Spanish painter and graphic artist who focused on the use of emotional language to convey meaning. His paintings are characterized by their seemingly ordinary subject matter, Continue Reading

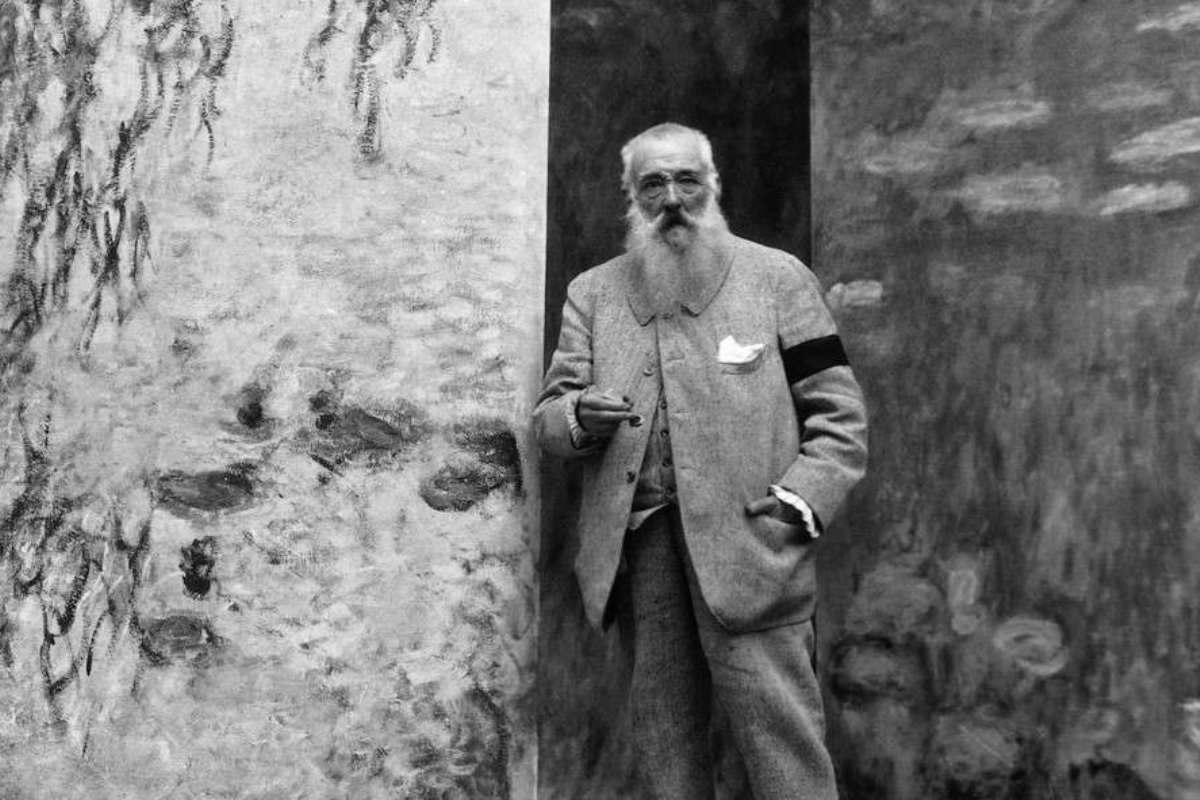

Claude Monet is one of the most well-known painters in history who is best known for his impressionist paintings and his works are some of the most popular pieces of Continue Reading

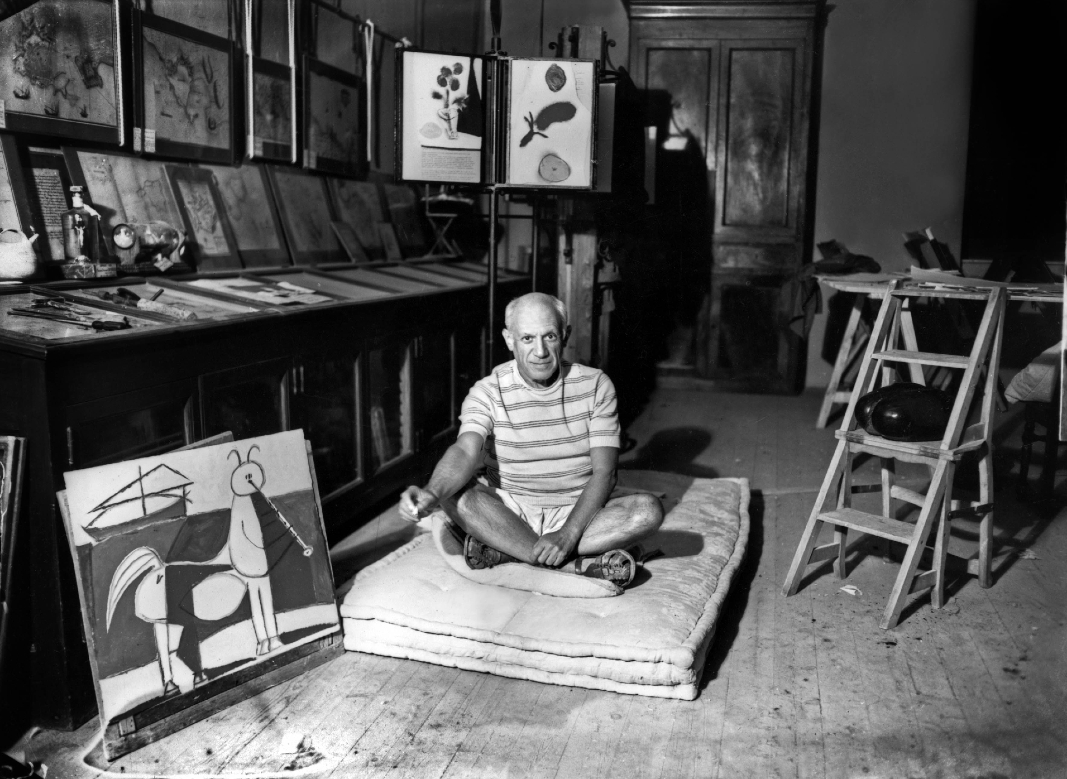

Picasso’s paintings are iconic and the most influential in modern art. His work is studied by many artists, and he is still considered one of the most important painters. Pablo Continue Reading